Products » ARENA model sand filters (single)

ARENA model sand filters (single)

ARENA model sand filters

Static sand or grit filtering system

|

Manual Arena part numbers and flow rates »

Automatic Arena part numbers and flow rates»

|

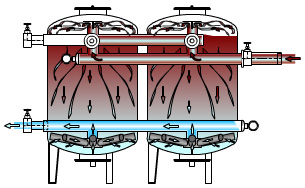

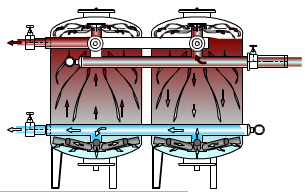

Specific filtration requirements for waters intended to irrigation or micro-irrigation in agriculture request sand filtration systems. The filtration process takes place with the passage of water from the top to the bottom through the grit layers. Modelli:

The manual and automatic individual versions are available in the following dimensions: from Ø 500 mm to Ø 1200 mm, with flow rates from 200-400 liters/minutes to 1200-2400 liters/minutes.

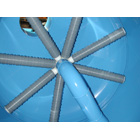

Battery versions configurations from 2x, 3x, 4x, 5x, 6x, 8x with diameters that go from Ø 500 mm to Ø 1200 mm. These filters and the frame are completely manufactured in painted or zinc-coated steel. In the inside lower part, Arena filters are equipped with filtering arms with 0,25 mm nozzles through which water flows outside. Applications

Being this a static drop filtration system, it is suitable to any kind of filtration of waters coming from:

Filtration rate: It equals a filtration rate of: 100 µ. It assures the trapping of very small particles such as:

It is advisable to mount upstream, a pre-filter such a Hydrocyclone that can remove up to 90% sand and solid particles or a screen filter. Back-washing: Versions, part numbers, flow rates |

Click on the images to see images

Images:

Send your request!

Send your request!

Hai bisogno di un´┐Żapplicazione

per un impianto particolare?

Vuoi un filtro "su misura"?

« Enter »

Send your request!

Send your request!

Need spare parts for ironing or dry cleaning industry?

« Enter »

Via Emilia n° 51/E 40011- Anzola dell’Emilia (Bologna) - Italy

Tel.: +39 (051) 73.21.90 - info@omparenti.com

P.IVA e C.F.: 02577301209 NUMERO REA: BO - 450522 ISCRITTA NELLA SEZIONE ORDINARIA IL 03/08/05

CAPITALE SOCIALE VERSATO : € 10.000,00 €