Products » Automatic filtering groups PROFESSIONAL SYSTEM

Automatic filtering groups PROFESSIONAL SYSTEM

FILTRATION OF EMULSIFYING AND COOLING LIQUIDS

Automatic filtering groups PROFESSIONAL SYSTEM

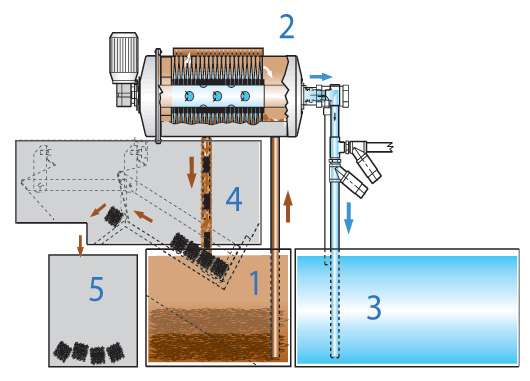

Automatic filtering group with self-cleaning filtering discs ideal for Companies specialised in accuracy mechanical works (filtration of emulsifying and cooling liquids).

|

Click to enlarge » |

In certain manufacture contests, emulsifying and cooling liquids filtration requires highly evolved systems or groups; automatic filters which can self-activate also for the self-cleaning of the system itself, by keeping constant the quality and quantity of filtered liquid and expelled waste. The filters frame is made of Stainless Steel AISI 304. The machine Body, the bearing frame and the chambers are made of painted steel. The system core is made of polyester filtering discs by us patented » (see)

The manufacture technology tested also in other industrial contests, makes this system an autonomous group. In the complete configuration all is carried out automatically: self-cleaning, recovery, drain and solid metal waste disposal. Applications It filtrates liquids coming from industrial processes, cut emulsifying, washing liquids and so on..

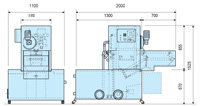

It ensures filtration speed and the utmost recovery of interesting liquids ( economic saving in the long term). Filtration rate The filtration rate ranges from 5 to 500 microns, according to the filtering discs used inside the filters. Operation in filtration: see figure beside The liquid to be filtered (1) is taken from a collection bath and conveyed inside the tangential flow spin filter (2) which is equipped with a number of patented high filtration degree filtering discs.

The filter self-cleaning cycles from residuals cumulated inside are automatically carried out with the same impure liquid destined to filtration » (see) During the self-cleaning cycle the system continues filtration. No manufacture stop occurs. Filtration is continuous and constant in time (filtration never stops). Maintenance Part numbers, flow rate and filtering surface |

Click on the arrows to slide images

Images:

Send your request!

Send your request!

Hai bisogno di un�applicazione

per un impianto particolare?

Vuoi un filtro "su misura"?

« Enter »

Send your request!

Send your request!

Need spare parts for ironing or dry cleaning industry?

« Enter »

Via Emilia n° 51/E 40011- Anzola dell’Emilia (Bologna) - Italy

Tel.: +39 (051) 73.21.90 - info@omparenti.com

P.IVA e C.F.: 02577301209 NUMERO REA: BO - 450522 ISCRITTA NELLA SEZIONE ORDINARIA IL 03/08/05

CAPITALE SOCIALE VERSATO : € 10.000,00 €